Sustainability and AI-Driven Digitalization for a Circular Industry at Celsa Group

As part of INDPULS‘s commitment to the digital and sustainable transformation of the industrial sector, we visited the Barcelona plant of one of our key partners: Celsa Group, the European leader in low-emission circular steel production.

Celsa is the largest European producer of circular economy steel and operates the continent’s most extensive circular supply chain. Its model is based on recycling ferrous scrap using electric arc furnaces, currently the most sustainable and energy-efficient method for steel production.

The group consists of various business units and a broad network of facilities including steel mills, rolling mills, recycling plants (circular hubs), and processing and distribution companies. This structure allows Celsa to directly and indirectly employ over 10,000 professionals across Europe, including 4,544 in Spain.

Climate Strategy and Sustainable Goals

Celsa actively addresses two of the 21st century’s key systemic challenges: resource scarcity and climate change. To that end, the company has set long-term strategic goals:

Reduce CO₂ emissions by 50% by 2030

Achieve 98% circularity in its processes by the same year

Become a Net Positive, zero-waste company by 2050, fully closing its circular cycle

Innovation as a Driver of Change

Anna Casals, Director of Innovation for CELSA Group in Spain and France, presented Celsa’s innovation strategy, which aligns with its Net Positive vision and is built around four key pillars: energy and emissions, circularity, people, and digitalization.

-

Energy and Emissions: Enhancing energy efficiency, integrating renewable energy sources, and developing and using alternative fuels such as green hydrogen and biochar.

-

Circularity: Optimizing scrap handling and developing new circular business models focused on steel and related areas.

-

People: The human factor is essential. All innovation initiatives originate from talent and cross-disciplinary collaboration.

- Digitalization: Leveraging artificial intelligence, advanced simulation, and digital twins to enhance processes, traceability, and develop digital product passports.

At Celsa, digitalization is conceived as a strategic tool for competitiveness—not as an end in itself.

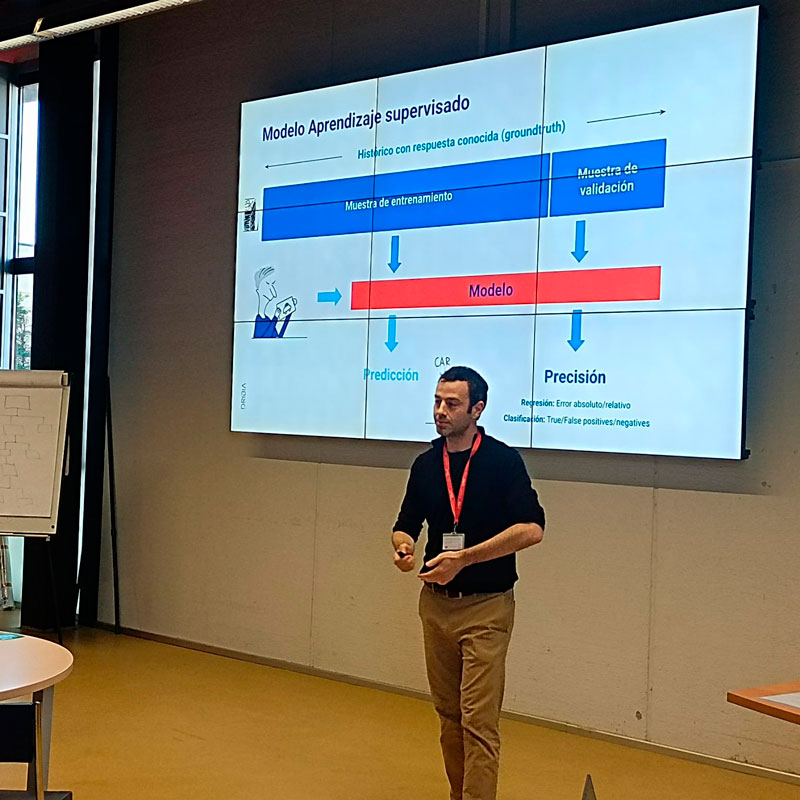

Accordingly, Celsa’s Innovation Department promotes multiple initiatives based on artificial intelligence and digital twins, using them as key tools to predict and optimize industrial consumption. This was previously discussed in “Artificial Intelligence Applied to Industry 4.0, by Dr. Oleguer Sagarra (DRIBIA)“.

One of the most notable success stories is the DAIMA Project, led by Juanjo Luna, Enterprise IT Architect at CELSA, and developed in collaboration with DRIBIA. By applying advanced AI techniques, they created a highly effective model for automatic scrap classification.

Pol Colomer, co-CEO of DRIBIA, and Antonio Lozano, Data Science Manager, provided a detailed overview of the AI architecture used in the project, highlighting key learnings and the benefits this type of solution brings in terms of safety, automation, bias prevention, and claim reduction.

Innovating Through Networks: A Paradigm Shift

During the visit to the Celsa Barcelona plant, we were joined by representatives of INDPULS partner companies and affiliates, as well as strategic expert and current president of Sarah Marlex, Xavier Marcet. In his talk, Marcet stated that “Innovation requires a new way of thinking.”

In today’s world, networks outperform individual nodes, and the most impactful innovation happens in shared spaces.

In this context, he recommended the book “Cascades: How to Create a Movement that Drives Transformational Change”by Greg Satell, co-founder of ChangeOS. The book argues that real change does not stem from grand speeches, but from small groups connected by a common purpose, who synchronize their actions and evolve into powerful networks capable of deep transformation.

This approach reflects the essence and purpose of INDPULS: collaborative innovation between companies and startups to create value, share knowledge, and strengthen the industrial ecosystem. We believe in innovation as a lever for economic, social, and environmental progress—with a sustainable impact on the region.

Many thanks to the CELSA team—Anna Casals, Director of Innovation in Spain and France; Laia Soler, Corporate Innovation; Juanjo Luna, IT Infrastructure Architect; and Laura Gómez, Head of Scrap Classification—for your warm welcome and for sharing your knowledge and experience with us.