The Methodology for Successful Innovation, According to Carina Solsona

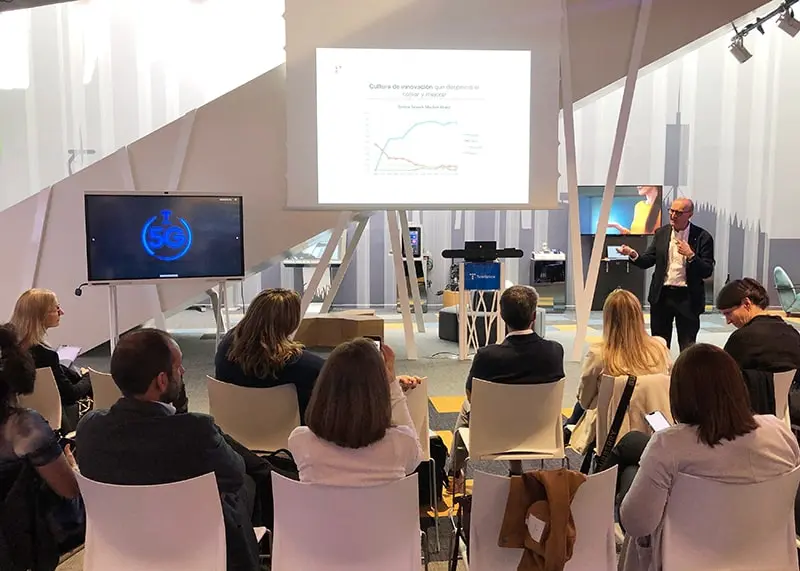

“Innovation Management: From Idea Generation to Operational Excellence” was the title of the presentation given by Carina Solsona, Senior Director of Engineering for the “Fabric Care” division in Europe and IMEA, at Procter & Gamble, during the strategy, innovation, and new challenges conference organized by INDPULS at Vallformosa.

Carina Solsona brings over 25 years of experience at the multinational Procter & Gamble, during which her leadership and innovation have contributed to global business growth of 40% and profit increases of 60%. She has achieved these successes by optimizing supply chain design and driving a profound shift toward operational excellence, enabled by automation and digital transformation. Leading a team of 400 engineers, her transformative leadership has left its mark on various markets, including the U.S., Latin America, Europe, and IMEA (India, the Middle East, and Africa).

Carina Solsona’s talk to INDPULS members focused on the methodology she uses to ensure innovation success.

“Innovation is not just having ideas; it’s making them a reality from start to finish in a way that brings value, is fast, economically sustainable, and achieves proper productive efficiency. We start with an idea, but we must end with an efficient, sustainable value chain that delivers the best possible results,” explained the Procter & Gamble executive.

The innovation framework proposed by Solsona is based on three distinct parts. It starts with rapid-cycle learning to filter ideas, moves on to a technical preparation process to determine how to make the idea work, and concludes with managing the innovation life cycle—ensuring that innovation does not stop at a one-off achievement but continues with ongoing improvement.

“Should we work on it?”

For the first phase, Solsona applies a methodology she developed about eight years ago, which remains effective and helps to filter and validate good ideas. “The process has five stages and begins with a very powerful question: ‘Should we tackle this idea? Should we work on it?’ To answer this question, you must consider what the problem is, what can be achieved by solving it, and whether there is a client who needs it,” she explained.

Second, the “how” must be assessed, and here she advises forming small, multidisciplinary teams. “I find teams of three people work well—for instance, one person from engineering, one from research, and one from operations. This team is given flexibility, a limited budget, and a coach or sponsor to guide them and provide additional resources if needed. From there, we must apply the LoFA (Leap of Faith Assumption) matrix to identify opportunities that require more evidence and those with greater potential to derail the project. It’s a process where intuition plays a role because there are many assumptions.”

The third stage of this methodology involves building and measuring. In this testing phase, milestones must be established on timelines to evaluate what can be learned and concluded within specific time windows—15, 30, and 60 days. “It’s very important to set these timeframes for deliverables and establish success metrics and evaluation criteria.”

The next step is validation, a process that must also be based on metrics to decide what will work and what should be discarded before making significant investments. This involves validating the Minimum Viable Product (MVP) to reduce uncertainty when launching a new product or process.

In fifth place, Carina Solsona applies the traffic light approach of the three Ps: pivot, persevere, and pass. In her words: “Some ideas need iterations—they look promising but require going back and trying again; with others, you must persevere because you’re on the right track and meeting the metrics; and some don’t work, so they need to be killed off. It’s an iterative process that should lead to learning.”

“How to Make Things Work”

The second phase of Solsona’s innovation framework focuses on the technical preparation process to ensure the new product or technology works, with the key being to view innovation as a transformation and to learn at every step.

Solsona’s proposal for this phase is the 5 Ms model. These are five subphases, each defined by an English term starting with M: Model, Mini testing, Macro testing, Manufacturing, and Measure. These subphases overlap significantly at the beginning, but as the process advances, there is progressively less overlap. However, the final subphase, Measure, extends throughout the entire process, as it intervenes in all the subphases. “The better we work on the first subphase, the better the subsequent ones will go—you’ll spend fewer resources, and everything will be more efficient. You should always work with a plan, validation metrics, and a flexible roadmap, all aimed at learning and continuous improvement.”

Continuous Improvement Cycle

In the third and final phase of innovation, Carina Solsona discusses managing the innovation lifecycle: “There are few disruptive innovations and many incremental ones. This is very clear in the digital world, where we see various versions of software or apps. But continuous improvement should apply to all innovations, including products. Before an innovation becomes obsolete and needs to be withdrawn from the market, it must be constantly improved.”

In conclusion, Solsona emphasized four points:

- Organization: Choose the right teams and foster the right mindset for growth, as innovation must be part of a business’s strategy.

- Speed of Disruption: Innovation should be somewhat flexible, guided by success criteria rather than time. Imposing strict timelines on innovation stifles team development. However, when acceleration is necessary, providing a methodological framework, rhythm, and tools helps shorten solution development time.

- Stop in Time if Necessary: Fall in love with the problem you need to solve, not the solution you propose, as it may (and likely will) change.

- Integrate End-to-End Innovation: Achieve better operational excellence by integrating sustainability, digital transformation infrastructure, future legal frameworks, and value creation aligned with the company’s strategic plan.

“This is a very organized method for innovating, but the first thing is not to be afraid—fear paralyzes. You need a ‘growth mindset,’ never say ‘never,’ and always think about how to keep improving. Don’t wait for the perfect plan—start, learn, try…,” added this leader, who throughout her career has turned challenges into remarkable opportunities.

It was a truly educational presentation that INDPULS members followed with great interest, aware of the importance of innovation in the industrial sector.